Gas transportation around globe is primarily done by ocean gas carriers and regional transport is done through pipelines.

Transportation of gas by gas carrier vessels is regulated under The International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code).

Transport of gases in packaged form by sea is regulated by IMDG Code.

During transport gas may be in any 5 of below physical conditions

- Compressed gas: a gas which when packaged under pressure for transport is entirely gaseous at –50°C; this category includes all gases with a critical temperature less than or equal to –50°C;

- Liquefied gas: a gas which when packaged under pressure for transport is partially liquid at temperatures above –50 °C. A distinction is made between: high pressure liquefied gas: a gas with a critical temperature between –50°C and +65°C, and low pressure liquefied gas: a gas with a critical temperature above +65°C;

- Refrigerated liquefied gas: a gas which when packaged for transport is made partially liquid because of its low temperature;

- Dissolved gas: a gas which when packaged under pressure for transport is dissolved in a liquid phase solvent;

- Adsorbed gas – a gas which when packaged for transport is adsorbed onto a solid porous material resulting in an internal receptacle pressure of less than 101.3 kPa at 20°C and less than 300 kPa at 50°C.”

Carriage of gas has various risks in ocean transport and the risk varies with the properties of gas involved. For safe carriage requirement gases are classified into

2.1 Flammable gases

2.2 Non-flammable, non-toxic gases

2.3 Toxic gases

Among all classes of dangerous goods the most deadliest is Class 2.3 (Toxic gases). The moment toxic gas escapes from its containment it can kill. This is the reason why IMDG Code prohibits stowage of empty uncleaned packages of class 2.3 under deck though empty uncleaned packages of other classes are permitted to be stowed under deck even if stowage under deck when full is prohibited

Gas may be permitted for transport in cylinders, tubes, Pressure drums, bundles or cylinders, MEGCs or tanks. It is the shippers responsibility to select the authorized and appropriate packaging for transporting gas.

Gases which are heavier than air is a silent killer when leaked under deck as it may settle on the bottom of the cargo space.

Class 2.2 includes oxidizing gases which can cause or contribute to fire. The oxidizing property of gases is to be determined according to ISO standard 10156:2010

While moving cylinders into containers and securing same, person in charge must ensure cylinders are not subject to rough handling, rolling on the floor or striking violently against each other. Rough handling of cylinders may cause delayed explosion for acetylene gas.

Due to the shape of the cylinders there are options for labeling according to part 5 of IMDG Code which permits reduced size labels to be secured on the shoulder of cylinder. This method of labeling must meet the conditions of ISO 7225:2005 “Gas cylinders – Precautionary labels”.

There are different packing instructions for chemical under pressure, gases, cryogenic receptacles & metal hydride storage system and there are articles and equipment which contain gas example Aerosols, refrigerating machines, pneumatic components etc. Classification of these article are basis the hazardous class of gas contained and the quantity.

Refrigerating machines containing less than 12 KG class 2.2 gas is excpempted from the requirement of IMDG Code. Similarly aerosols of class 2.2 with less than 50 ml capacity and not having any toxic substances are exempted.

Tanks designed to carry refrigerated liquefied helium is a special equipment. These tanks contain liquefied nitrogen to absorb the heat from helium and keep it in liquid form through the journey. Helium is non toxic, odorless and colorless gas with boiling point at sea level -268.9 deg C. There are special operational methods to keep the tank operating to maintain the pressure and temperature of helium with the help of nitrogen. Generally the shipper’s representative will board the vessel and instruct the ship staff how to achieve this.

Liquefied helium when escapes from tank is extremely low in temperature which can cause dangerous cryogenics burns and embrittlement of carbon steel.

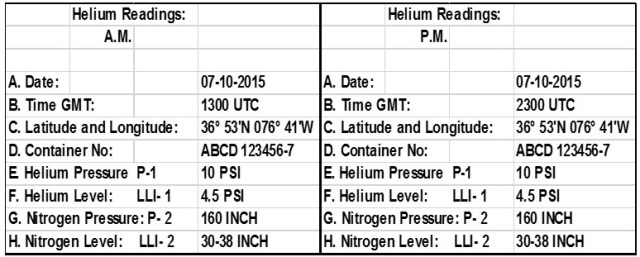

When loaded on vessel ship staff will send out daily readings to shipper which includes below parameters.

Exemptions under class 2 ( gases ) are listed in chapter 2.2 of IMDG Code which includes

- Gases of class 2.2 if they are transported at a pressure of less than 200 kPa at 20°C and are not liquefied or refrigerated liquefied gases

- Foodstuffs (except UN 1950), including carbonated beverages;

- Balls intended for use in sports;

- Tyres (except for air transport);

- Light bulbs provided they are packaged so that the projectile effects of any rupture of the bulb will be contained within the package ( see 1.1.1.9 of IMDG Code for more details on lamps).

For carriage on board ships, the Document of compliance with the special requirements for ships carrying dangerous goods under the provisions of regulation II-2/19 has separate entries for Classes 2.1, 2.2, 2.3 flammable & 2.3 non flammable gases.

Segregation Table of IMDG Code 37-14 is amended for Class 2.1 as Separated from Class 4.3.

WhatsApp your queries

WhatsApp your queries